Custom Wine Cellars Denver, one of the most reliable wine cellar installers in

Custom Wine Cellars Denver Based in Denver is a Full-Service Custom Wine Cellar Installer, Supplier, and Builder

Denver, has extensive experience in the construction industry. We listed down some of the wine cellar problems and the reason for their occurrence, and expert solutions to prevent them from damaging your wine investment, including the role of the wine cellar cooling system in saving your collection from spoilage.

Common Problems That You Will Encounter After Working with a Non-Expert and How Professional Wine Cellar Installers Denver Can Help

When you work with a builder who does not have extensive knowledge and experience in wine cellar construction, you cannot expect your wines to preserve their desirable characteristics for many years.

Failure to consult with expert wine cellar installers Denver will cause significant problems related to wine storage. At Custom Wine Cellars Denver, we always make sure that everything is working correctly. We install high–grade materials and equipment because we care for our client’s wine collection and enjoyment.

We had clients before who reported that they were experiencing one or more of the following conditions in their wine cellar:

- Condensation formation and mold growth in the wine cellar

- A noisy wine cooling system

- Their refrigeration unit stops producing cold air or breaks down

- The temperature and humidity levels were not stable

- There were spoiled wines in their collection

These wine storage issues are caused by the incorrect installation of one of the components (vapor barrier, insulation, wine cellar cooling unit, and door. It pays to work with an expert installer of refrigerated wine cellars. Below are the causes of wine storage problems

1. Not Installing a Vapor Barrier in Your Wine Cellar

The vapor barrier also plays a crucial role in regulating the conditions in refrigerated wine cellars. It provides a break between the climate-controlled wine room and the spaces around it. When the cold air in your wine cellar comes in contact with the warm air in your home or restaurant, there will be condensation.

A vapor barrier will prevent moisture formation that can trigger mold growth in the walls and ceiling, on the cork, and on wine labels. The material will depend on the type of insulation to be used. A 6-mil polyethylene vapor barrier is ideally used with traditional batting or rigid foam insulation.

2. Inadequate or Poor Wine Room Insulation by Your Chosen Wine Cellar Installers in Denver

After framing the room, one crucial step that should not be neglected is the insulation of the walls and ceiling. The correct insulation in your wine cellar is necessary will keep the cold air from escaping and the warm air from entering.

At Custom Wine Cellars Denver, we always ensure that the insulation has a sufficient R-value. A minimum of R-19 insulation value is recommended. Inadequate insulation will cause temperature fluctuations and cause your wine cooling system to overwork. In the long run, your wine cellar refrigeration units will be needing a repair or replacement due to breaking down. Moreover, unstable conditions will affect the quality of your wines.

Keep in mind that the remedy for poor insulation will require removing the walls and ceiling, which means you will have to spend a hefty amount of money on the materials and labor.

When it comes to efficiency and cost-effectiveness, closed-cell foam spray insulation is the best option. It provides a higher insulation value compared to other types of insulation. It can expand and fill all the gaps and cracks, and it also creates a tight seal around piping and wiring that goes through one or more walls in your wine cellar.

Additionally, it will save you money because it can act as both an insulator and a vapor barrier. You will not need plastic sheeting for your vapor barrier.

3. The Wrong Wine Cooling System is Installed in Your Wine Cellar

After preparing the wine cellar (framing, electrical work, and insulation), the wine refrigeration system can be installed by Denver HVAC experts. However, when the cooling unit does not suit the size and location of your wine cellar, there is no way you will enjoy its benefits. Instead, you will encounter problems such as wine spoilage, mold growth, and decreased lifespan of your equipment.

At Custom Wine Cellars Atlanta, our team makes a thorough assessment of our client’s needs and requirements before choosing the type, size, capacity, and brand of wine cooling system to be utilized for a particular project. We offer commercial-grade wine refrigeration units designed to provide maximum performance in regulating the temperature and humidity in wine cellars.

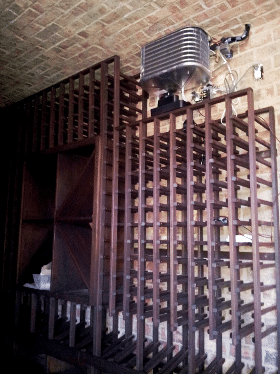

Look at the commercial wine cellars we have installed.

4. The Wine Cellar Doors are Not Sealed Completely by Your Installer

Another reason why a wine storage problem occurs is that your wine cellar door is not sealed completely or appropriately. Your door should not only increase the aesthetic value of your home or commercial establishment. It should also be constructed to keep your wine collection safe.

As a professional designer and installer, Custom Wine Cellars Denver manufactures wood, wrought iron, and glass wine cellar doors with the capacity to seal and insulate climate-controlled wine rooms. Our team uses closed-cell foam insulation to fill in the gap between the rough opening and the jamb of the door. It is the same type of insulation we use for the walls and ceiling. Moreover, we equip all of our doors with weather stripping on all the edges to prevent air leakage in your wine cellar.

Another essential sealing component for your wine cellar door is the automatic door bottom, which creates a seal between the door and the floor. It is beneficial because it helps keep the cold air inside the wine cellar by closing the door automatically when your hands are full, or you forgot to close the door. It drops down just before the door shuts and retracts when the door is opened.

Another advantage of this mechanical device is that it does not damage your floor due to door dragging.

5. The Wine Cellar Doors are of Low-Quality

When constructing wine cellar doors, we always keep in mind that they will be installed in a wine room equipped with a wine cooling system. At Custom Wine Cellars Denver, all of our doors are exterior grade so they can withstand the humid conditions in climate-controlled wine cellars.

Our durable wooden doors are 1 ¾” thick and constructed using a technology called the LVL (Laminated Veneer Lumber). We use adhesives to connect the layers of thin wood to increase the durability and warp resistance of our doors.

For seamless glass doors or wrought iron doors with glass, we use glass panels with 5/8” thickness, dual-paned, and are thermally insulated. These properties of glass will help create a highly insulated wine cellar and prevent moisture build-up.

Avoid Wine Storage Problems. Work with a Master Wine Cellar Installer in Denver!

Vailrature and humidity are two factors that contribute to the overall quality of the wine. Consulting with expert wine cellar installers Denver will ensure that your wine room is built with high-grade components and installed correctly by a professional.

With extensive experience and knowledge in wine cellar construction, our team will build your dream wine cellar ideal for long-term storage. We offer a hassle-free experience and exceptional customer service to our clients.

If you need help with your project or have any questions about design and installation of refrigerated wine cellars, please call us today at (303) 872-7858!

Check out some of the wine cellar refrigeration projects equipped with wine cooling units from a trusted manufacturer.